Sculpteo Overview

Sculpteo offers an online 3D printing service for producing 1-100k parts. With numerous technologies and material options, parts are manufactured quickly and efficiently.

Use Cases

Customers recommend Proposal & Quote Management, Market Research, Collaboration, as the business use cases that they have been most satisfied with while using Sculpteo.

Business Priorities

Acquire Customers and Enter New Markets Internationally Or Locally are the most popular business priorities that customers and associates have achieved using Sculpteo.

Sculpteo Use-Cases and Business Priorities: Customer Satisfaction Data

Sculpteo's features include Feedback Surveys. and Sculpteo support capabilities include Chat Support, 24/7 Support, Email Support, etc. also Sculpteo analytics capabilities include Custom Reports, and Analytics.

Reviews

"...In the same way crowdfunding allows hardware startups to rapidly market test their products, Sculpteo's 3D printing technologies accelerate their development cycles...." Peer review by Richard Ollier, Chief Executive Officer, Giroptic

Sculpteo Customer wins, Customer success stories, Case studies

How does Sculpteo address your Proposal & Quote Management Challenges?

Why is Sculpteo the best choice for Market Research?

11 buyers and buying teams have used Cuspera to assess how well Sculpteo solved their business needs. Cuspera uses 139 insights from these buyers along with peer reviews, customer case studies, testimonials, expert blogs and vendor provided installation data to help you assess the fit for your specific business needs.

Sculpteo Features

- Low

- Medium

- High

| FEATURE | RATINGS AND REVIEWS |

|---|---|

| Custom Reports | Read Reviews (30) |

| Analytics | Read Reviews (26) |

| CAPABILITIES | RATINGS AND REVIEWS |

|---|---|

| Custom Reports | Read Reviews (30) |

| Analytics | Read Reviews (26) |

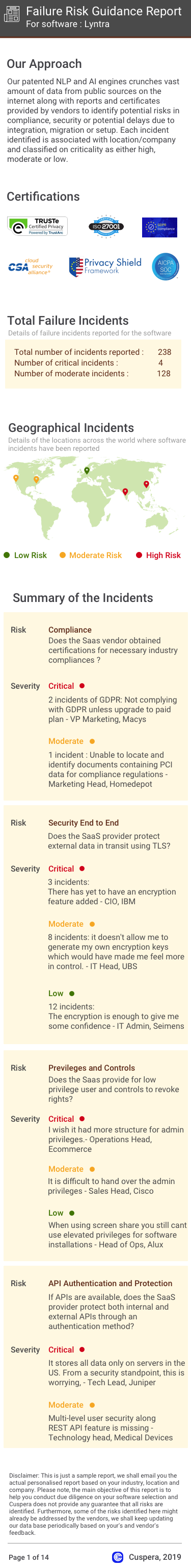

Software Failure Risk Guidance

?for Sculpteo

Top Failure Risks for Sculpteo

Sculpteo SAS News

French non-profit My Human Kit partners with Sculpteo to develop open-source bionic prosthetics - 3D Printing Industry

Sculpteo has partnered with French non-profit My Human Kit to develop open-source bionic prosthetics. This collaboration leverages Sculpteo's advanced 3D printing technology to create personalized, functional prosthetics like the Bionicohand. The partnership aims to improve accessibility and customization of prosthetics, addressing challenges faced by amputees in obtaining affordable and specialized devices.

My Human Kit collaborates with Sculpteo for 3D printed prosthetics - Med-Tech Insights

Sculpteo and My Human Kit have partnered to produce 3D-printed prosthetics, enhancing accessibility to personalized and sustainable prosthetic solutions. This collaboration utilizes Sculpteo's industrial-grade 3D printing materials to create functional prototypes, such as the Bionicohand, an open-source bionic hand. The partnership aims to address the high cost and lack of personalized prosthetics by offering adaptable and aesthetically pleasing models.

Sculpteo releases Fabpilot smoother 3D printing workflow solution

Sculpteo has launched Fabpilot, a cloud-based 3D printing workflow solution designed to enhance manufacturing agility and flexibility. Fabpilot integrates project management, 3D data preparation, and plant operations, supporting over 30 CAD/3D file types. It offers features like digital analysis, quality control, and job prioritization, facilitating seamless collaboration and production optimization. The platform is available as a free trial on Sculpteo's website.

Sculpteo's Public API - 3D Printing Industry

Sculpteo has launched its 3D Printing Cloud Engine API to the public, enabling developers and businesses to integrate 3D printing capabilities into their websites and applications. This API allows users to upload, repair, and display 3D models, and facilitates ordering 3D prints directly from their platforms. The move positions Sculpteo competitively against rivals like 3D Hubs, Shapeways, and i.materialise.

Sculpteo SAS Profile

Company Name

Sculpteo SAS

Company Website

//sculpteo.com/enHQ Location

Villejuif

Social